- Email: info@example.com

- 380 Albert St, Melborne

Call: +1(230)-456-155-23

Call: +1(230)-456-155-23

HAMMER UNIONS

- Home

- HAMMER UNIONS

HAMMER UNIONS

General

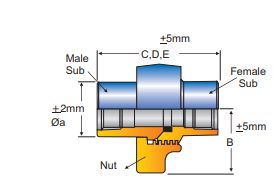

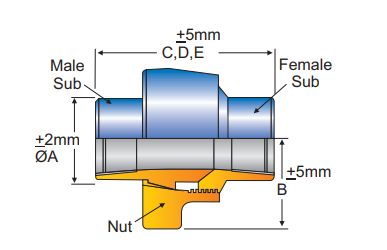

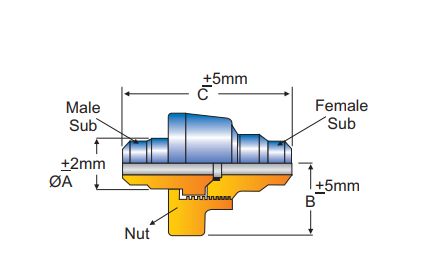

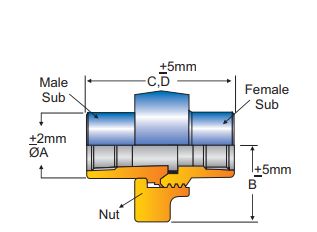

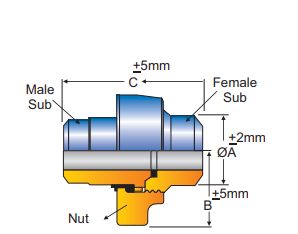

In sizes ranging from 1 to 12 inches and with ratings up to 20,000 PSI cold working pressure, BALAJI produces Hammer Unions using raw materials in the form of forgings or castings, in line with service requirements. Additionally, we manufacture Hammer Unions for sour gas service in compliance with NACE MR-01-75 and API RP-14E standards.

Thread Gauging

Standard plug and ring gauges are used to measure Acme thread and line pipe thread gauges.

Sealing Design

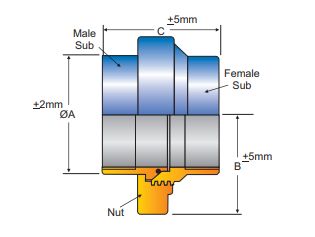

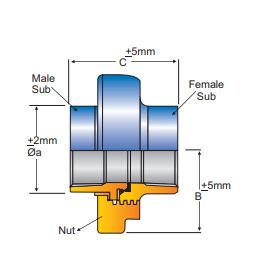

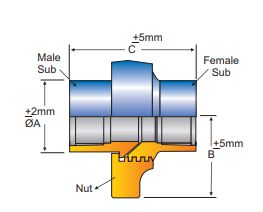

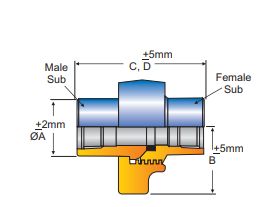

For low-pressure services, the conical and spherical surfaces of the female and male subs respectively create a reliable metal-to-metal seal.

For medium pressure applications, an ‘O’ ring is typically included in the male sub along with the metal-to-metal seal. For high pressure applications, a lip-type seal ring serves as the primary seal in the female sub, protecting the secondary metal-to-metal seal from corrosion and limiting fluid flow turbulence. In sour service applications, viton seals are used.

Quality Control

At BALAJI, we employ contemporary manufacturing techniques to achieve superior workmanship and dimensional control in the production of Hammer Unions. We carefully select raw materials appropriate for a specific service and utilize the appropriate heat-treatment process to ensure extended durability and better performance under extreme conditions.

1. Line pipe threads in Fig-1002, Fig 1502 for Pipe diameters above 4″ are not’ recommended for sour service application.

2. For Fig-1003, 4″ & 5″ sizes are rated at ,7500 PSI cold working pressure and 12000 PSI test pressure.

3. Sour gas service unions are painted OLIVE GREEN and stamped “NACE”.

4. For other types of threading like casing, tubing or NPS thread seal configuration, consult factory

| FIGURE # | COLOR CODING | PRESSURE RATING (psi) | NOMINAL PIPE SIZES | ||||||||||||||

| Standard Service | |||||||||||||||||

| NSCWP | Test | 0.5" | 0.75" | 1" | 1.25" | 1.5" | 2" | 2.5" | 3" | 4" | 5" | 6" | 8" | 10" | 12" | ||

| 100 |  | 1,000 | 1,500 | ||||||||||||||

| 110 |  | 2,500 4,000 | 3,750 6,000 | ||||||||||||||

| 200 |  | 2,000 | 3,000 | ||||||||||||||

| 201 |  | 3,000 | 4,000 | ||||||||||||||

| 206 |  | 2,000 | 3,000 | ||||||||||||||

| 207 |  | 2,000 | 3,000 | ||||||||||||||

| 211 |  | 2,000 | 3,000 | ||||||||||||||

| 300 |  | 2,000 2,500 12,500 | 3,000 3,750 18,750 | ||||||||||||||

| 400 |  | 4,000 | 6,000 | ||||||||||||||

| 602 |  | 6,000 | 9,000 | ||||||||||||||

| 607(CGC) |  | 6,000 | 9,000 | ||||||||||||||

| 1002 |  | 10,000 | 15,000 | ||||||||||||||

| 1003 |  | 7,500 10,000 | 11,250 15,000 | ||||||||||||||

| 1502 |  | 15,000 | 22,500 | ||||||||||||||

Fig 50. Orange Nut - Orange Subs

These low pressure and suction union of Fig-50 are made from carbon steel. The nut and O-ring are common in both sizes. Available in 4″ or 5″ sizes in threaded & socket welded connection. These unions are suitable for 500 PSI wp.

| Size (Inch) | A | B | C | ACME (TPI) | UNION | WEIGHT | |||||||

| Inch | mm | Inch | mm | Threaded | Socket Welded End | Threaded | Socket Welded End | ||||||

| Inch | mm | Inch | mm | lbsf | kgf | lbsf | kgf | ||||||

| 4" | 6 | 152.5 | 5.07 | 129.0 | 6.15 | 156.21 | 4.12 | 104.64 | 3MOD | 28 | 12.7 | 27 | 12.24 |

| 5" | 6 | 152.5 | 5.07 | 129.0 | 5.77 | 146.74 | 4.12 | 104.64 | 3MOD | 23 | 10.43 | 21.5 | 9.75 |

Fig 100. Black nut - Yellow subs

These low pressure unions are ideal for manifold and applications where CWPdoes not exceed 1000 PSI.

| Size (Inch) | A | B | C | ACME (TPI) | UNION | WEIGHT | |||

| Inch | mm | Inch | mm | Inch | mm | LBSF | KGF | ||

| 1 | 1.6 | 40.5 | 1.95 | 50 | 2.57 | 65 | 6STD | 1.75 | 0.79 |

| 2 | 2.74 | 69.5 | 2.91 | 74 | 3.66 | 93 | 3MOD | 5.73 | 2.6 |

| 2 1 /2 | 3.3 | 84 | 3.81 | 97 | 4.29 | 109 | 3MOD | 9.47 | 4.3 |

| 3 | 4.09 | 104 | 4.09 | 104 | 4.88 | 124 | 3MOD | 1.33 | 6.05 |

| 4 | 5.19 | 132 | 5 | 127 | 5.78 | 147 | 3MOD | 19.84 | 9 |

| 5 | 6.37 | 162 | 5.75 | 146 | 6.03 | 153 | 4STD | 33 | 15 |

| 6 | 7.36 | 187 | 6.92 | 176 | 6.71 | 170.5 | 3STD | 46 | 20.9 |

| 8 | 9.52 | 242 | 8 | 203 | 7.2 | 183 | 3STD | 61.72 | 28 |

Fig 200. Blue Nut - Grey subs

These unions are best suited for medium pressure ranges involving air, water, oil & gas service for cold working pressure upto 2,000 PSI. (For dimensions see fig. 206). Upto 4” no O-ring is used on the male sub. Beyond 4” size, an O-Ring is used on the male sub for sealing.

Fig 206. Blue Nut - Grey subs

These unions have an additional ‘O’ ring on the spherical surface of the male sub providing a leak proof seal. All dimensions of fig:- 200 & Fig-206 are identical.

| Size (Inch) | A | B | C | ACME (TPI) | UNION | WEIGHT | |||

| Inch | mm | Inch | mm | Inch | mm | LBSF | KGF | ||

| 1 | 1.59 | 40.5 | 1.96 | 50 | 2.55 | 65 | 6STD | 1.76 | 0 80 |

| 1 1 /4" | 2 | 51 | 2.11 | 53.6 | 2.79 | 71 | 6STD | 2.2 | 1 |

| 1 1 /2" | 2.28 | 58 | 2.52 | 64 | 2.73 | 69.5 | 6STD | 2.42 | 1.1 |

| 2 | 2.79 | 71 | 2.91 | 74 | 3.54 | 90 | 4STD | 5 | 2.3 |

| 2 1 /2 | 3.3 | 84 | 3.87 | 98.5 | 4.25 | 108 | 4STD | 9.25 | 4.2 |

| 3 | 4.17 | 106 | 3.89 | 99 | 4.52 | 115 | 4STD | 13.67 | 6.2 |

| 4 | 5.23 | 133 | 4.52 | 115 | 4.96 | 126 | 3MOD | 18.52 | 8.4 |

| 5 | 6.32 | 162 | 5.75 | 146 | 6.03 | 153 | 4STD | 33 | 15 |

| 6 | 7.5 | 190.5 | 6.06 | 154 | 6.65 | 169 | 3STD | 42.5 | 19.3 |

| 8 | 9.56 | 243 | 7.18 | 182.5 | 7.15 | 181.5 | 3STD | 61.7 | 28 |

| 10 | 11.49 | 292 | 9.01 | 220.7 | 9.09 | 231 | 3STD | 90.39 | 41 |

Fig 207. Blue Cap - Grey Subs

These banking unions have a resilient ‘O’ ring in the blanking cap to provide an efficient and leak-proof seal suitable for 2000 PSI CWP.

| Size (Inch) | A | B | C | ACME (TPI) | UNION | WEIGHT | |||

| Inch | mm | Inch | mm | Inch | mm | LBSF | KGF | ||

| 3 | 4.09 | 104 | 2.91 | 74 | 3.74 | 95 | 4STD | 10.36 | 4.7 |

| 4 | 5.15 | 131 | 3.58 | 91 | 4.33 | 110 | 3MOD | 16.3 | 7.4 |

| 6 | 7.55 | 192 | 5 | 127 | 5.9 | 150 | 3STD | 38.13 | 17.3 |

| 8 | 9.6 | 245 | 6.1 | 155 | 6.1 | 220 | 3STD | 70.76 | 32.1 |

| 10 | 11.53 | 293 | 7.16 | 182 | 7.16 | 248 | 3STD | 96.11 | 43.6 |

Fig. 211. Blue Subs - Grey Nut

These unions protect against electrolytic action. There is no metal – to – metal contact between the subs. A resilent seal ring in the female sub provide additional sealing and protection from corrosion. Suitable for 2000 PSI CWP.

| Size (Inch) | A | B | C | ACME (TPI) | UNION | WEIGHT | |||

| Inch | mm | Inch | mm | Inch | mm | LBSF | KGF | ||

| 1 | 1.57 | 40 | 2.09 | 53 | 2.72 | 69 | 6STD | 2.2 | 1 |

| 1 1 14" | 2.2 | 56 | 2.43 | 62 | 3 | 76 | 6STD | 3.7 | 1.68 |

| 1 1 2" | 2.2 | 56 | 2.43 | 62 | 3 | 76 | 6STD | 3.2 | 1.45 |

| 2 | 2.84 | 72.2 | 3.07 | 78 | 3.49 | 88.8 | 4STD | 6.4 | 2.9 |

| 2 1 /2 | 3.38 | 86 | 3.67 | 93 | 4.13 | 105 | 4STD | 9.7 | |

| 3 | 4.09 | 104 | 3.96 | 101 | 4.45 | 113 | 4STD | 15.8 | 7.16 |

| 4 | 5.12 | 130 | 4.68 | 119 | 4.84 | 123 | 3MOD | 18.4 | 8.34 |

| 6 | 7.56 | 192 | 7.25 | 184 | 7.21 | 183 | 3STD | 43.5 | 19.6 |

| 8 | 9.62 | 244 | 8.75 | 222 | 9.12 | 232 | 3STD | 65.5 | 29.5 |

Fig 400. Black Nut - Red Subs

These unions are rigid in design and have all the three parts made of steel forgings. These unions are best suited for manifold and line connections. Unions from 3 inch through 8 inch sizes have O- rings for primary sealing. From 5” to 8” sizes C.W.P. is 2,500 PSI.

| Size (Inch) | A | B | C | ACME (TPI) | UNION | WEIGHT | |||

| Inch | mm | Inch | mm | Inch | mm | LBSF | KGF | ||

| 1 | 1.57 | 40 | 2.09 | 53 | 2.72 | 69 | 6STD | 2.2 | 1 |

| 1 1 14" | 2.2 | 56 | 2.43 | 62 | 3 | 76 | 6STD | 3.7 | 1.68 |

| 1 1 2" | 2.2 | 56 | 2.43 | 62 | 3 | 76 | 6STD | 3.2 | 1.45 |

| 2 | 2.84 | 72.2 | 3.07 | 78 | 3.49 | 88.8 | 4STD | 6.4 | 2.9 |

| 2 1 /2 | 3.38 | 86 | 3.67 | 93 | 4.13 | 105 | 4STD | 9.7 | |

| 3 | 4.09 | 104 | 3.96 | 101 | 4.45 | 113 | 4STD | 15.8 | 7.16 |

| 4 | 5.12 | 130 | 4.68 | 119 | 4.84 | 123 | 3MOD | 18.4 | 8.34 |

| 6 | 7.56 | 192 | 7.25 | 184 | 7.21 | 183 | 3STD | 43.5 | 19.6 |

| 8 | 9.62 | 244 | 8.75 | 222 | 9.12 | 232 | 3STD | 65.5 | 29.5 |

Fig. 600. Silver Subs - Black Nut

These unions have wide range of applications including steam service and line connections. These unions are provided with a bronze seat in the female for the effective sealing and prevention of rust formation. Suitable for 6000 PSI CWP.

| Size (Inch) | A | B | C | ACME (TPI) | UNION | WEIGHT | |||

| Inch | mm | Inch | mm | Inch | mm | LBSF | KGF | ||

| 1 | 1.75 | 44.5 | 2.26 | 57.5 | 3.58 | 91 | 6STD | 3.52 | 1.6 |

| 1 1 /2 | 2.55 | 65 | 3.07 | 78 | 4.92 | 125 | 4STD | 9.26 | 4.2 |

| 2 | 3.07 | 78 | 3.7 | 94 | 6.42 | 163 | 2STD | 15.43 | 7 |

| 2 1 /2 | 3.54 | 90 | 4.17 | 106 | 7.52 | 191 | 2STD | 20.28 | 9.2 |

| 3 | 4.25 | 108 | 4.54 | 115.5 | 8.72 | 221.5 | 2STD | 27.23 | 12.4 |

| 4 | 5.27 | 134 | 5.19 | 132 | 10.04 | 255 | 2STD | 40 | 18.1 |

Fig 602. Orange Subs - Black Nut

These unions are recommended for manifold and line connections truck mounting and in mud services. This union has resilient lip-type seal for positive sealing and also protects secondary metal – to metal seal. Suitable for 6000 PSI.

| Size (Inch) | A | B | C | BUTT WELDED END D | ACME (TPI) | UNION | WEIGHT | ||||

| Inch | mm | Inch | mm | Inch | mm | Inch | mm | LBSF | KGF | ||

| 1 | 1.75 | 44.5 | 2.28 | 58 | 3.5 | 89 | 3.5 | 89 | 6STD | 3.3 | 1.5 |

| 11-4 | 2.6 | 66 | 3.23 | 82 | 4.88 | 124 | 4.88 | 124 | 4STD | 11 | 5 |

| 1 1 /2 | 2.56 | 65 | 3.06 | 77.8 | 4.88 | 124 | 4.88 | 124 | 4STD | 9.7 | 4.4 |

| 2 | 3.07 | 78 | 3.81 | 97 | 5.25 | 133.5 | 5.28 | 133.5 | ЗМОО | 12.12 | 5.5 |

| 2 1 /2 | 3.51 | 89.1 | 3.75 | 95.5 | 6.24 | 158.5 | 5.59 | 142 | ЗМОО | 15.87 | 7.2 |

| з | 4.25 | 108 | 4.52 | 115 | 6.22 | 158 | 5.62 | 143 | ЗМОО | 20.94 | 9.5 |

| 4 | 5.27 | 134 | 5.04 | 128 | 8.23 | 209 | 5.67 | 144 | ЗМОО | 30.86 | 14 |

Fig 1002. Blue Subs - Red Nut

These unions are designed for high pressure systems like choke and kill lines, cementing , acidizing, testing and truck mounted system. This union has a liptype seal made of nitrile rubber and subs made of alloy steel, suitable for 10,000 PSI.

| Size (Inch) | A | B | C | BUTT WELDED END | ACME (TPI) | UNION | WEIGHT | ||||||

| D SCH-160 | E SCH-XXS | ||||||||||||

| Inch | mm | Inch | mm | Inch | mm | Inch | mm | Inch | mm | LBSF | KGF | ||

| 1 | 1.75 | 44.5 | 2.28 | 58 | 3.5 | 89 | 3.5 | 89 | 3.5 | 89 | 6STD | 3.5 | 1.6 |

| 1 1 /4 | 2.6 | 66 | 2.95 | 75 | 4.88 | 124 | 4.88 | 124 | 4.88 | 124 | 4STD | 9.7 | 4.4 |

| 1 1 /2 | 2.55 | 65 | 3.18 | 81 | 4.88 | 124 | 4.88 | 124 | 4.88 | 124 | 4STD | 9.25 | 4.2 |

| 2 | 3.07 | 78 | 3.81 | 97 | 5.25 | 133.5 | 5.28 | 133.5 | 5.28 | 133.5 | 3MOD | 12.12 | 5.5 |

| 2 1 /2 | 3.46 | 88 | 3.78 | 96 | 6.18 | 157 | 6.18 | 157 | 6.18 | 157 | 4STD | 16 | 7 |

| 2 1 /2(EUE) | 3.81 | 97 | 4 | 100 | 5.51 | 140 | - | - | - | - | 4STD | 17.8 | 8.1 |

| 3 | 4.25 | 108 | 4.52 | 115 | 6.22 | 158 | 5.51 | 140 | 5.51 | 140 | 4STD | 22.26 | 10 1 |

| 4 | 5.27 | 134 | 5.04 | 128 | 8.23 | 209 | 5.67 | 144 | 5.67 | 144 | 4STD | 33 | 15 |

| 5 | 5.55 | 141 | 6.1 | 155 | 6.22 | 158 | 6.22 | 158 | 6.22 | 158 | 3STD | 56 | 254 |

| 6 | 6.62 | 168.3 | 6.81 | 173 | 6.57 | 167 | 6.57 | 167 | 6.57 | 167 | 3STD | 79.8 | 36.2 |

Fig 1003. Green Subs - Black Nut

These unions have a ball seat incorporating a primary ‘O’ ring seal with a metal secondary seal which assures perfect 0 0 sealing in misalignment position. Degree of misalignment upto 2” size is 4 and beyond 2” size it is 7 1 /2 . This union is ideally suited for use on high pressure lines. Available in 10000 PSI with end threaded or butt- welded for welding.

| Size (Inch) | A | B | C | Beveled Ends | ACME (TPI) | UNION | WEIGHT | ||||||

| D Sch-160 | E Sch-xxs |

||||||||||||

| Inch | mm | Inch | mm | Inch | mm | Inch | mm | Inch | mm | OBS | KGF | ||

| 1 | 1.77 | 45 | 2.36 | 60 | 5 | 127 | 5 | 127 | 5 | 127 | 4STD | 5 | 2.3 |

| 2 | 3 | 76 | 3.86 | 98 | 4.8 | 122 | 4.8 | 122 | 4.8 | 122 | 4STD | 12.6 | 5.7 |

| 3 | 4.29 | 109 | 4.96 | 126 | 9.17 | 233 | 8.82 | 224 | 9.17 | 233 | 4STD | 44.5 | 20 |

| 4 | 5.43 | 138 | 5.74 | 146 | 10.94 | 278 | 10.78 | 274 | 10.98 | 279 | 4STD | 73 | 32.8 |

| 5 | 5.62 | 143 | 6.74 | 146 | 10.78 | 274 | 10.98 | 279 | 6STD | 73 | 32.8 | ||

Fig 1004. Red Nut - Grey Subs

These union use lip type seal ring end here faces of male and female sub are perfectly square. These are available in 5″ & 6″ butt weld sizes.

| Size (Inch) | A | B | C BEVELED ENDS | ACME (TPI) | UNION | WEIGHT | ||||

| Inch | mm | Inch | mm | Inch | mm | lbsf | KGF | |||

| 5 | 6.3 | 160 | 6.5 | 165.1 | 8.15 | 207 | - | 86 | 39 | |

| 6 | 7.4 | 189 | 7.2 | 182.8 | 9.5 | 241.3 | - | 142 | 64 | |

Fig 1502. Blue Nut - Pink Subs

These unions are widely used in cementing, manifold and other services wherein extra high pressures of 15,000 PSI CWPare encountered. These unions are provided with replaceable seal ring.

| Size (Inch) | A | B | C | BEVELED ENDS D | ACME (TPI) | UNION | WEIGHT | ||||

| Inch | mm | Inch | mm | Inch | mm | Inch | mm | LBSF | KGF | ||

| 1 | 2.18 | 55.5 | 2.75 | 70 | 4.33 | 110 | 4.33 | 110 | 3.5STD | 8.5 | 3.8 |

| 1.1 /2 | 2.96 | 75.2 | 3.48 | 88.5 | 5.39 | 137 | 5.39 | 137 | 3.5STD | 12.8 | 5.7 |

| 2 | 3.22 | 82 | 3.86 | 98 | 7.03 | 178.5 | 6.3 | 160 | 3STD | 20.3 | 9.2 |

| 2.1 12 | 3.74 | 95.2 | 3.96 | 100 | 7.28 | 185 | 7.08 | 180 | 3STD | 23 | 10.3 |

| 3 | 4.45 | 113 | 4.53 | 115 | 7.67 | 195 | 5.28 | 134 | 3.5STD | 29.5 | 13.3 |

| 4 | 5.75 | 146.1 | 6 | 152 | 8.54 | 217 | 10.55 | 268 | 3MOD | 76.5 | 34.4 |

| 5 | 6.45 | 164 | 6.53 | 166 | - | - | 9 | 230 | - | 96 | 43 |

| 6 | 7.48 | 190 | 7.2 | 183 | - | - | 9.8 | 249 | - | 148 | 67 |

Fig 2002. Green Nut - Grey Subs

These unions are provided with replacement lip-type seal and are recommended for choke and kill lines, cementing, acidizing and testing services for pressure up to 20,000 PSI CWP.

Fig 2202. (H2S) - Olive Green

These unions are specially designed for sour gas service in accordance with NACE Std. MR-01-75 and API Std. RP14E for pressure up to 15000 PSI CWP. Dimensions identical with Fig-2002 above.

| Size (Inch) | A | B | C BEVELED ENDS | ACME (TPI) | UNION | WEIGHT | ||||

| Fig. | Fig. | |||||||||

| Inch | mm | Inch | mm | Inch | mm | 2002 | 2202 | lbsf | KGF | |

| 2 | 2.5 | 63.5 | 3.75 | 95.2 | 7.44 | 189 | 4 | 5 | 22.6 | 10.1 |

| 3 | 5.38 | 136.7 | 6 | 152 | 10.51 | 267 | 4 | 5 | 49 | 22.2 |

| 4 | 5.5 | 139.7 | 6 | 152 | 8.65 | 220 | - | - | 77.5 | 35.1 |

| 5 | 6.12 | 155.4 | 6.55 | 166 | 10.9 | 277 | - | - | 112 | 50.8 |

| 6 | 7.75 | 197 | 7.3 | 185 | 13.2 | 335 | - | - | 169 | 76.7 |